Description

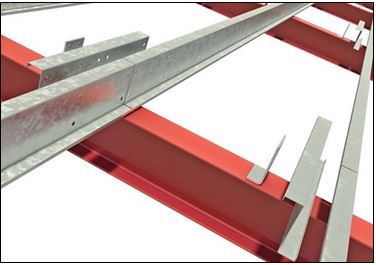

Al-Buhsain Steel Industries “JMB Panel” manufacture a complete range of structural C and Z section purlins and girts for a wide range of applications. Made from quality, high tensile galvanized steel, Al-Buhsain Steel Industries “JMB Panel” purlins and girts can be supplied plain or punched.

PURLINS

General Data

The “Z”- and “C” shaped sections of Al-Buhsain Steel Industries “JMB Panel” are accurately roll formed via cold forming from high-strength zinc-alloy coated steel in order to provide an efficient, lightweight and

cost-efficient roofing, cladding and walling support system, for framed

structures. (Purling and girt system).

Range of products and services

-

- The full range of “Z” and “C”- shaped

- Technical information for cleat less

- Bolting systems to suit all project

- Corrosion protection

- Technical advice on improving the life expectancy of purling systems in corrosive

- Access to a network of experienced

Applications

Al-Buhsain Steel Industries “JMB Panel” “Z” shaped section may be used over single spans, un-lapped continuous spans and lapped continuous spans

in multi-bay buildings. Lapped spans result in a considerable load bearing capacity increase in the system. Al-Buhsain Steel Industries “JMB Panel” “C” shaped section may be used over single spans and un-lapped continuous spans in multi-bay buildings. They are ideal as eave purlins or where compact sections are required. The “C” shaped section cannot be used in overlapping structures.

Material specifications – standards

The “Z” and “C” shaped section structural elements are manufactured through cold forming procedure from zinc-alloy coated steel Zinc-hi-ten® which minimum yield stress is by 60% higher than the respective profiles formed

through hot forming. This means that we can use sections of minimum

thickness and weight, resulting in reduction of the time and the cost of the construction. They are classified as “thin gauge member” profiles and the study as well as the analysis concerning their application is conducted according to

the provisions of the European standard EN 1993-1.3.

Base Metal Thickness (BMT) 1.5mm – 2.0mm – 2.5mm – 3.0mm

Steel Quality: G450 (according to AS 1397-93) or S450GD (according to EN 10147-2000) with guaranteed minimum yield stress of 450 N/mm².

Corrosion Protection

In standard production the material used is hot-dipped galvanized, type Z275, zinc-alloy coated (with a minimum coating density of 275 gr./m² ) steel (according to AS 1937-93 & EN 10147-100). Upon request, purlins can also be manufactured from hot dipped galvanized, type Z350, zinc alloy coated (with a minimum coating density of 350 gr/m²) steel, for applications in aggressive and severely corrosive environments.

Dimensions

Al-Buhsain Steel Industries “JMB Panel” “Z” and “C” shaped section are produced in standard dimension and length upon request from 2.000mm to 12.000mm according to the engineering design data. Are produced according to the desired hole punching with the following restriction:

- Minimum distance from the end section

- Minimum center holes distance in perpendicular axe

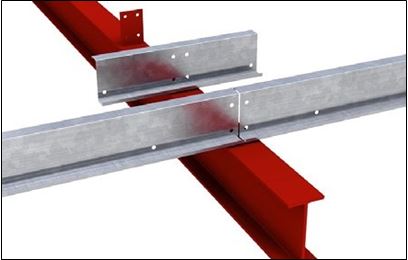

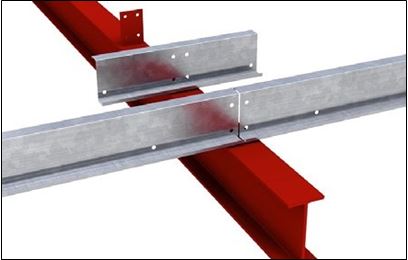

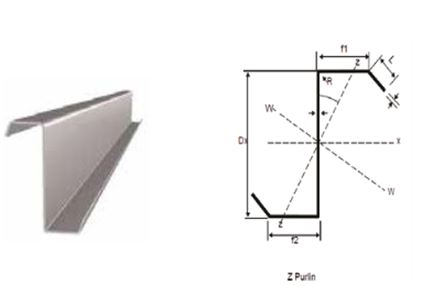

“Z”- shaped profiles

The “Z” shaped sections structural elements of Al-Buhsain Steel Industries “JMB Panel” feature two flanges of different width so that two elements with the same static height can overlap, fitting perfectly to each other. In this way, we achieve to bridge multiple spans with continuous purlins. This purlin fixing method is called continuous and

provides the advantage of practically doubling the purlin thickness at its fixing points, where bending moments and shear forces have maximum values, thus improving the load bearing capacity as well as the rigidity of the system. The structural elements of “Z” profiles with the same static height but different thickness can be overlapped in any combination.

Other fixing methods:

- Sleeve

- Freely supported continuous fixing

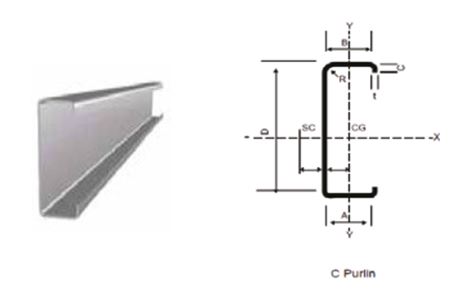

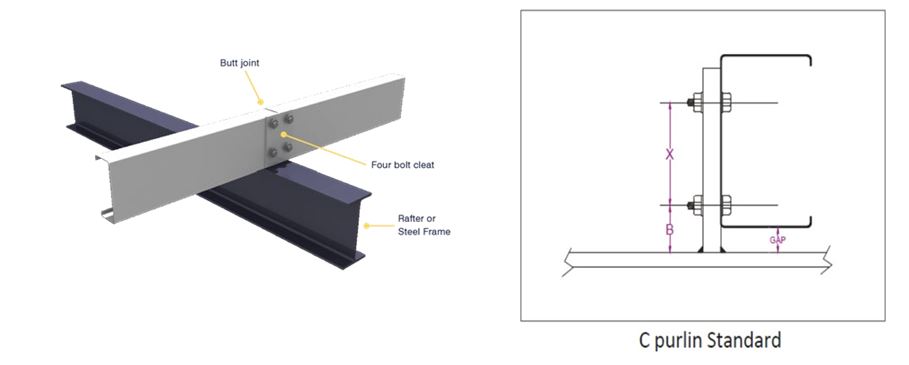

“C” shaped sections

The “C” shaped sections structural elements of Prime Insulated Panels feature two equally sized flanges and are ideal for use as purlins, girths as well as door and window frames. They cannot

be overlapped, and they are only installed freely supported over single spans or continuous spans with the ends butted

C Purlin

C Purling are horizontal structures that are used to support the load from the roof deck or the sheathing. The plane surface of this purling on one side has made it a preferred material for cladding due to its easy installation on concrete structures or steel. Our range purling is light in weight and perfect for simple span construction.

|

C Purlin SPECIFICATION |

|||

|---|---|---|---|

| Web | Flange | Lip | Thickness |

| 100 | 50 | 20 | 1.5 to 2mm |

| 140 | 70 | 20 | 1.5 to 2mm |

| 180 | 70 | 20 | 1.5mm/2mm/2.5mm |

| 210 | 80 | 20 | 1.6 to 3mm |

| 250 | 80 | 20 | 1.6 to 3mm |

| 300 | 80 | 20 | 1.6 to 3mm |

Z Purlin

Z Purlin are made using cold-formed or rolled sheets for supporting roof. The flexible shape of these beams facilitates various designs solutions. These purling are extensively used in huge roofing solutions such as godowns, workshops, industrials sheds and many more. The

range is known for saving up to 50% on structural sheet in comparison with hot rolled angles. Our purling is crisp and clean in design and do not allow the scope of inaccurate lengths

Z Purlin

Z Purlin are made using cold-formed or rolled sheets for supporting roof. The flexible shape of these beams facilitates various designs solutions. These purling are extensively used in huge roofing solutions such as godowns, workshops, industrials sheds and many more. The

range is known for saving up to 50% on structural sheet in comparison with hot rolled angles. Our purling is crisp and clean in design and do not allow the scope of inaccurate lengths

|

Z Purlin SPECIFICATION |

||||

|---|---|---|---|---|

| Web | Flange | Lip | Thickness | |

| 100 | 50 | 54 | 20 | 1.5 to 2mm |

| 140 | 70 | 60 | 20 | 1.5 to 2mm |

| 180 | 70 | 60 | 20 | 1.5mm/2mm/2.5mm |

| 210 | 80 | 70 | 20 | 1.6 to 3mm |

| 250 | 80 | 70 | 20 | 1.6 to 3mm |

| 300 | 80 | 70 | 20 | 1.6 to 3mm |

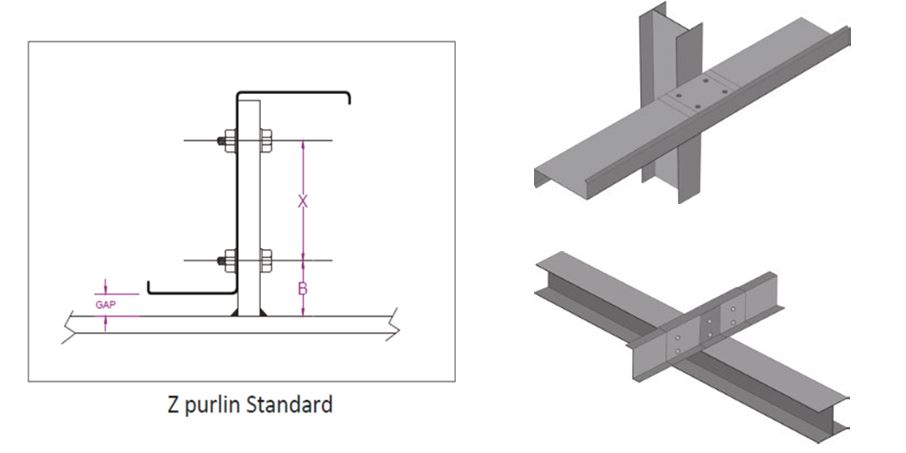

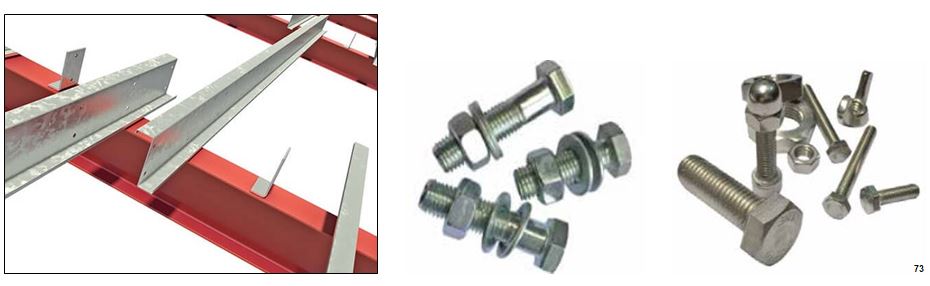

Z & C Purlins & Accessories

Purlins, Both C and Z, are available in various sizes rolled. They can be ordered plain or with Holes pre-punched, as per standard end punching or punched to any layout required. The standard maximum length for delivery of purlins is 12 meters. Lengths that are greater than 12 meters long are obtainable. However, they then require special delivery vehicles, pre-arranged delivery times and on-site handling capabilities.

C PURLINS: Sections have flanges which are equal in size and are commonly used for simple supported spans. C sections are not

lapped together, for continuous spans they are end butted.

Z PURLINS: Sections are made with one flange broader than the other. When one purlin is rotated 1800 two sections can be bolted together enabling them to be lapped. Lapping the purlins over interior supports improves the load capacity and rigidity of the purlins. Z sections purlins can also be used, like C sections, in the application of simple spans.

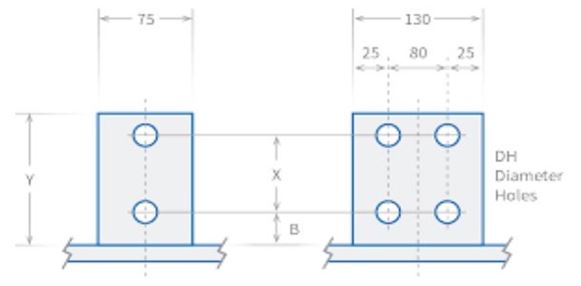

Standard Purlin/Rail Cleats

All holes 14 mm for 12 mm bolts.

Standard cleats are normally supplied back bare metal suitable for welding to rafters. By arrangement cleats can be supplied with additional holes in the base leg of angle cleats for bolting to rafters on site and supplied with a finish hot

dipped galvanized/or painted with standard primer.

| SET SCREWS – ZINC PLATED CLASS 8.8 METRIC FINE | |

|---|---|

| Name | ASTM F593 bolt |

| Size | M4-M100 1/4 – 4″ or non-standard (request & design) |

| Finish | Plain, Zinc Plated, Black Oxide, Hot Dip Galv.et |

| Head Type | Hex head |

| Material | Carbon steel, stainless steel, alloys steel etc. |

| Grade | a2, a4, 4.8, 8.8, 10.9, 12.9.etc, A2 -70, A4 -80 etc.. |

| Standard | GB, DIN, ISO, ANSI/ASTM, BS, BSW, JIS etc. |

| Non-Standards | OEM is available, according to drawing or samples |

| SIZE |

|---|

| M12 X 35 |

| M12 X 40 |

| M12 X 45 |

| M12 X 50 |

| M12 X 60 |

| M12 X 90 |

| M12 X 100 |